Particulate Matter (PM)

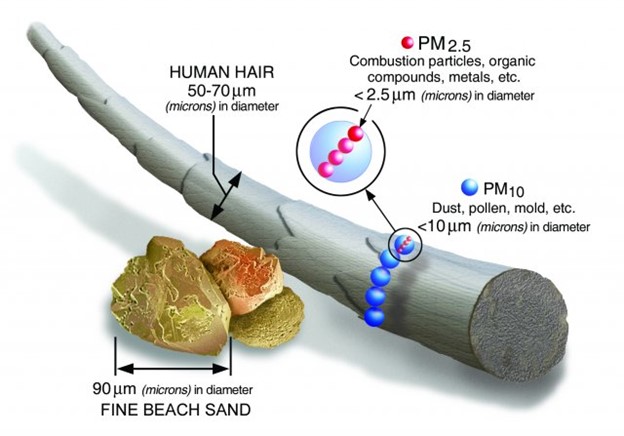

Also called particle pollution, PM is the mixture of solid particles and liquid droplets found in the air. PM is classified into two categories, PM2.5 and PM10. Often found in industrial processes, these particles are only detectable using an electron microscope and are regulated by the EPA.

What is Particulate Matter?

Particulate matter (PM), a.k.a particle pollution, is the mixture of solid particles and liquid droplets in the air. Classified as PM2.5, some particles, such as those found in gaseous or industrial emissions, metals, etc., are so small (≤ 2.5 microns), that detection is only possible using an electron microscope. On the other hand, dust, dirt, soot, or smoke, are large or dark enough to be seen by the naked eye and are classified as PM10.

Source: Environmental Protection Agency

Where does PM Come From?

Exhaust emissions from industrial smokestacks, transportation vehicles, and power plants contain PM2.5. PM2.5 has the potential to combine in the atmosphere due to chemical reactions. These reactions can form compounds such as sulfur dioxide and nitrogen oxides, which harm living organisms and the environment. PM10 commonly develops from agricultural and construction sites, unpaved roads, and fires.

White Snow Stained from Black Particulate Matter (PM) Emitted from an Industrial Boiler Stack

Why is Particulate Matter Regulated?

Both PM2.5 and PM10 are inhalable and can cause serious health problems. The EPA regulates inhalable particles, with regional and national rules to reduce PM pollutant emissions ≤ 10 microns.

Larger PM10 causes conditions such as eye and lung/throat irritation. PM2.5 creates a greater health risk since those fine particles can enter the bloodstream and be carried throughout the body – causing damage, illness, and worsening pre-existing health conditions. Infants, children, older adults, and people with heart or lung disease are highly affected by particle pollution. Particulate matter causes low birth weight, breathing problems such as asthma or emphysema, and increases risks of lung cancer, heart attacks, and strokes.

Industry Applications with Particulate Matter Emissions

- Transportation Electrification

- Recovery & Recycling

- Food Processing & Manufacturing

- Building Materials

- Petrochemical Processing

Technology Options for Particulate Matter

Treatment of particulate matter is accomplished using various industrial air control technologies. Pollution Systems provides industrial APC systems that effectively capture and remove particulate and any accompanying VOCS/HAPS. Choosing the right industrial system depends on the volume of particulate needing treatment, so our engineers will assess each industrial process situation to determine the best technology for your needs.

- Venturi Scrubbers – use water or other scrubbing fluids to capture smaller particulate from the dirty industrial process air stream.

- Multi-Vane Scrubbers (MVS) – ideal for handling much larger process air volumes, effectively eliminating particulate with high efficiency and almost no downtime.

- Recuperative Thermal Oxidizers – for lower energy exhaust, a Recuperative TO utilizes a shell and tube heat exchanger with the oxidizer to destroy the particulate while recovering energy for re-use.

Tailored Solutions for your PM Emissions

The proper solution for PM depends on the specific pollutant that needs treatment; therefore, it is difficult to say what system a facility needs without a detailed understanding of the application. Reach out to our technical sales group to understand the potential solutions based on your specific needs.

Glossary

Through the Clean Air Act, the EPA sets national standards for six criteria pollutants, including particulates (PM2.5 and PM10). These standards are reviewed and updated periodically, with the last revision on January 6, 2023. You can view the most current rulings for PM on the EPA site.

It is worth noting that although federal standards exist, your plant may be subject to more stringent requirements from local and state regulatory bodies.

Industrial wet scrubbers that are designed specifically for particulate matter (PM) removal. These air pollution control technologies effectively capture fine particles (≤ 2.5 microns) by injecting a scrubbing fluid into the exhaust stream with high velocity. Pollution Systems designs and manufactures particulate dust scrubbers to abate your PM emissions.

Particulate matter is considered a primary pollutant if it is directed emitted into the air. Activities that cause particle pollution on their own include:

- Construction and mining sites

- Smokestacks

- Biomass Buring

- Agricultural operations

- Some factories, dependent on the manufacturing processes

Particle pollution is considered secondary pollutants when it is formed by complex chemical reactions of gases in the atmosphere (usually due to the presence of sulfur dioxides and nitrogen oxides). Secondary pollutants form into ground-level ozone, smog, persistent organic pollutants (POP), and acid rain.

Industrial manufacturing can produce both primary and secondary PM pollution.

Related Case Studies

Food Manufacturer Resolves Process Complications With a Multi-Vane Scrubber

A food manufacturer experienced continuous operational issues due to wet, sticky particulates present in their cereal processing application. Pollution Systems designed a Multi-Vane Scrubber to successfully abate the PM build-up with minimal maintenance needs.

- Pollutant: Particulate Matter (PM)

- Industry: Food Processing & Manufacturing

- System: Wet Scrubbers

Multi-Vane Scrubber Captures Problematic Particulate at Food Facility

Using a Multi-Vane Scrubber, a food manufacturer abates particulate emissions from their food processing line.

- Pollutant: Particulate Matter (PM)

- Industry: Food Processing & Manufacturing

- System: Wet Scrubbers