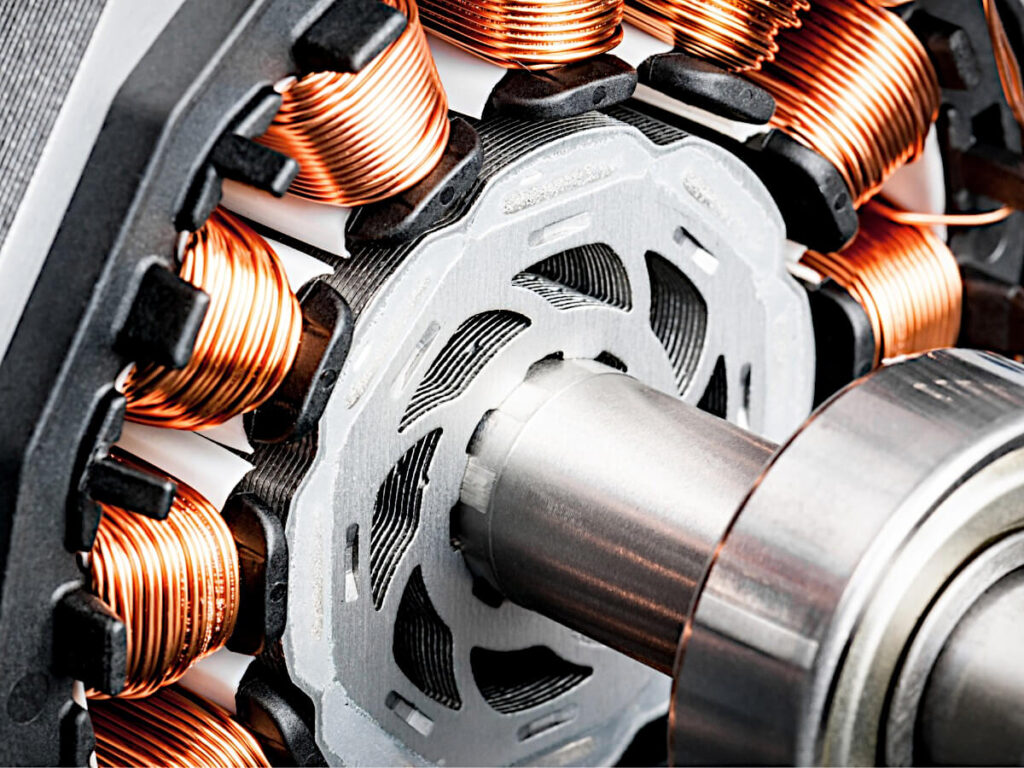

Metal Finishing

Metal Finishing processes can include grinding, polishing, etching, cleaning, coating, and laminating which generates dust (particle pollution). Paints, coatings, solvents, and laminates release vapors with varying amounts of Volatile Organic Compounds (VOCs), heavy metals, and Particulate Matter (PM) when applied, dried, or cured. The chemicals in such substances can react in the air to form ground-level ozone. Regulated by all levels of government, metal finishing operations must control emissions of these pollutants so that they stay compliant with operating permits.

Abatement Systems for Metal Finishing

All of our wet scrubbers and oxidizers are applicable to metal finishing operations, and the ultimate solution is dependent on the specific application and target pollutants.

- Particulate Dust Scrubbers – remove the dust and other particulates that result from grinding, polishing, and etching metal by injecting liquid to capture the particulate.

- Chemical Gas Scrubbers – react with contaminants in the exhaust gas to create a salt for removal.

- Recuperative Oxidizers – effective for exhaust streams with high VOC and particulate concentrations, such as those with solvents and specialty coatings. These oxidizers treat residue from cleaning, coating, and laminating processes.

- Catalytic Oxidizers – handle low, stable VOC concentrations and are practical for coating processes that do not release high levels of pollutants into the exhaust stream.

- Regenerative Thermal Oxidizers – are used for vapor with lower VOC and particulate concentrations and are highly energy-efficient abatement systems.

Effectively Abate Your Metal Finishing Emissions

Whether you are responsible for metal grinding or coating and laminating, metal finishing operations require air abatement technology that is tailored to the application. Our technical sales staff will work with your team to determine the proper solution.